In metallurgy, stainless steel is an alloy steel with a chromium content of at least 10.5% with or without other alloying elements and a carbon content of up to 1.2%. Stainless steel, also known as stainless steel or French stainless steel (inox), is a steel alloy known for its corrosion resistance, which increases with the chromium content. Corrosion resistance can also be improved by the addition of nickel and molybdenum.

The resistance of these metal alloys to the chemical action of corrosive agents is based on passivation.

In order for passivation to occur and remain stable, the iron-chromium alloy must have a minimum chromium content of approximately 10.5% by weight, above which passivation can occur and below which it is not possible.

Chromium can be used as a hardening element and is often used in conjunction with a hardening element such as nickel to produce superior mechanical properties.

Types of stainless steel

Stainless steel Stainless steel is a general term for a large group of corrosion resistant alloys containing at least 10.5% chromium and may contain other alloying elements.

There are many grades of stainless steel with different chromium and molybdenum contents and with different crystalline structures to suit the environment the alloy must withstand.

Stainless steels can be divided into five categories.

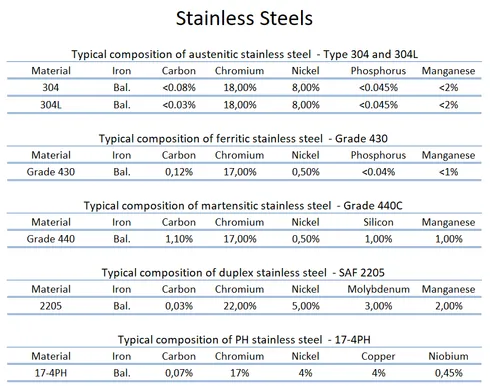

Ferritic stainless steels. In ferritic stainless steels, carbon is kept low (C < 0.08%) and the chromium content can range from 10.50 to 30.00%.

They are called ferritic alloys because they contain mainly ferritic microstructures at any temperature and cannot be hardened by heat treatment and quenching.

They are classified under the AISI 400 series designation. Although some ferritic grades contain molybdenum (up to 4.00%), only chromium is used as the main metal alloying element. Their use is usually restricted to relatively thin sections due to their lack of weld toughness. In addition, their resistance to high temperatures is relatively poor.

Ferritic steels are chosen for their resistance to stress corrosion cracking, which makes them an attractive alternative to austenitic stainless steels in applications where chloride-induced SCC is prevalent.

Austenitic stainless steels.

Austenitic stainless steels contain 16-25% chromium and possibly also nitrogen in solution, both of which contribute to their relatively high corrosion resistance. They are classified as AISI 200 or 300 series; the 300 series grades are chromium-nickel alloys, while the 200 series represents a group of compositions in which manganese and/or nitrogen replace some of the nickel.

Austenitic stainless steels have the best corrosion resistance of all stainless steels and have excellent low temperature properties and good resistance to high temperatures. They have a face-centred cubic (fcc) microstructure, are non-magnetic and can be easily welded.

This austenitic crystalline structure is achieved by the addition of sufficient austenitic stabilising elements of nickel, manganese and nitrogen.

Austenitic stainless steels are the largest family of stainless steels, accounting for approximately two-thirds of all stainless steel production. Their very low yield strength (200 to 300 MPa) limits their use in structural and load-bearing components.

They cannot be hardened by heat treatment, but have the useful property of being work-hardened to high strength levels while retaining useful levels of ductility and toughness. In such cases, duplex stainless steels are often preferred because of their high strength and corrosion resistance. They cannot be hardened by heat treatment, but have the useful properties of being work-hardened to high strength levels while retaining useful levels of ductility and toughness.

In this case, duplex stainless steels are often preferred because of their high strength and corrosion resistance. They cannot be hardened by heat treatment, but have the useful properties of being work hardened to high strength levels while retaining useful levels of ductility and toughness.

Duplex stainless steels are often preferred in this case because of their high strength and corrosion resistance. The best known grade of stainless steel tubing is AISI 304 stainless steel, which contains chromium (between 15% and 20%) and nickel (between 2% and 10.5%) as its main components.

Martensitic stainless steels.

Martensitic stainless steels are similar to ferritic steels in that they are chromium-based but have a higher carbon content of up to 1%.

They are sometimes classified as low-carbon and high-carbon martensitic stainless steels. They contain 12-14% chromium, 0.2-1% molybdenum and no significant amount of nickel.

The higher carbon content allows them to be hardened and tempered in the same manner as carbon and low-alloy steels. They have moderate corrosion resistance, but are considered hard, strong and slightly brittle. They are magnetic and can be tested non-destructively by magnetic particle inspection methods, unlike austenitic stainless steels. A common martensitic stainless steel is AISI 440C, which contains 16-18% chromium and 0.95-1.2% carbon.

Grade 440C stainless steel is used for the following applications: pattern blocks, cutlery, ball bearings and races, dies, and tools. As written, martensitic stainless steels can be hardened and tempered by various forms of aging/heat treatment. The metallurgical mechanisms responsible for the martensitic transformation that occurs during austenitization and quenching of these stainless steel alloys are essentially the same as those used to harden alloys and carbon steels with lower alloy content.

Heat treatment generally consists of three steps. The metallurgical mechanisms leading to the martensitic transformation of these stainless steels during austenitization and quenching are essentially the same as those used for the lower alloy content of hardening alloys and carbon steels. Heat treatment generally consists of three steps. The metallurgical mechanisms leading to martensitic transformation of these stainless steels during austenitization and quenching are essentially the same as those used to harden the lower alloy content of alloys and carbon steels.

Heat treatment generally consists of three steps.

Austenitizing of martensitic stainless steels, in which the steel is heated to a range of 980 – 1050°C, depending on the grade. Austenitizing is a face-centered cubic phase.

Quenching.

After austenitizing, the steel must be quenched and tempered. Martensitic stainless steel alloys can be quenched using still air, positive pressure vacuum or intermittent oil quenching. Austenitizing transforms to martensite, a tetragonal crystal structure centered on a hard body. Martensite is too hard and brittle for most applications.

Tempering.

This means heating to about 500°C, holding the temperature, and then air quenching. Increasing the tempering temperature decreases yield strength and ultimate tensile strength, but increases elongation and impact strength.

Duplex stainless steel.

Duplex stainless steels, as the name implies, are a combination of two major alloy types.

They have a mixed microstructure of austenite and ferrite, which is usually intended to produce a 50/50 mix, although in commercial alloys the ratio may be 40/60. Their corrosion resistance is similar to that of their austenitic counterparts, but their resistance to stress corrosion cracking (especially chloride stress corrosion cracking), tensile strength and yield strength (about twice the yield strength of austenitic stainless steels) is usually better than austenitic stainless steels.

In duplex stainless steels, carbon is kept at a very low level (C < 0.03%). Chromium content varies from 21.00 to 26.00% and nickel content varies from 3.50 to 8.00%, and these alloys may contain molybdenum (up to 4.50%). Toughness and ductility are usually between austenitic and ferritic grades.

Duplex grades are generally divided into three subgroups based on their corrosion resistance: depleted duplex, standard duplex and super duplex. Compared to standard austenitic steels, super duplex steels offer higher strength and resistance to all forms of corrosion.

Common uses are in marine applications, petrochemical plants, desalination plants, heat exchangers and the paper industry. Currently, the oil and gas industry is the largest user and has pushed for more corrosion resistant grades, leading to the development of super duplex steels.

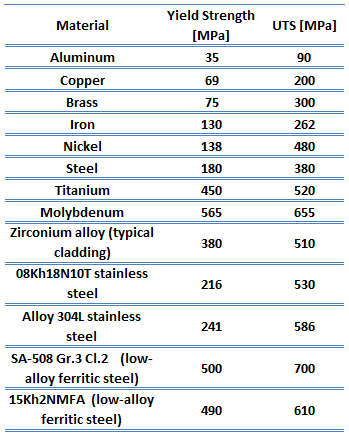

Strength of Stainless Steel

In the mechanics of materials, the strength of a material is its ability to support an applied load without failure or plastic deformation.

The strength of a material basically considers the relationship between the external load applied to the material and the resulting deformation or change in the dimensions of the material. The strength of a material is its ability to support this applied load without failure or plastic deformation.

Tensile Strength

Type 304 stainless steel has a maximum tensile strength of 515 MPa.

The maximum tensile strength of stainless steel-Type 304L is 485 MPa.

The maximum tensile strength of ferritic stainless steel – type 430 is 480 MPa.

Maximum tensile strength of martensitic stainless steel – grade 440C is 760 MPa.

Duplex stainless steel – SAF2205 has a maximum tensile strength of 620 MPa.

The maximum tensile strength of precipitation hardening steel – 17-4PH stainless steel depends on the heat treatment process, but is approximately 1000 MPa.